Natural diamonds take billions of years to form at extreme pressures and temperatures underground.

Synthetic forms can be produced much faster, but they need to be heavily pressurized, often for several weeks.

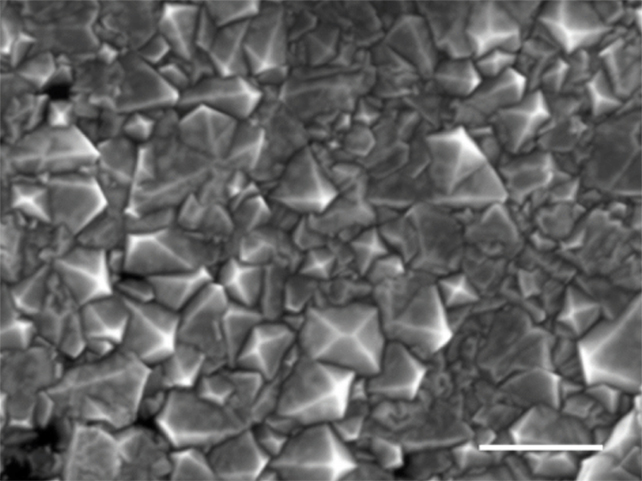

A new method, based on a mixture of liquid metals, can mine an artificial diamond in a few minutes without the need for massive compression.

At a temperature of 1,25 degrees Celsius in an ATM (standard atmospheric unit), a diamond film was created in 150 minutes.

This is equivalent to the pressure we feel at sea level and tens of thousands of times less than the pressure normally required.

The team behind the innovative approach, led by researchers from South Korea's Institute of Basic Science, is confident that the process can be scaled up to make a significant difference in the production of synthetic diamonds.

Melting carbon into liquid metal for diamond production is not entirely new. For example, a process using molten iron sulfide was developed half a century ago.

But these processes still required pressures of 5-6 gigapascals and a diamond 'seed' for the carbon to attach to.

"We have discovered a method of growing diamonds at 1 atm pressure and moderate temperature using a liquid metal alloy," the researchers said in their published paper.